Australian Tanks Offer Precast Concrete Pump Stations That Offer Peace-of-Mind Installation.

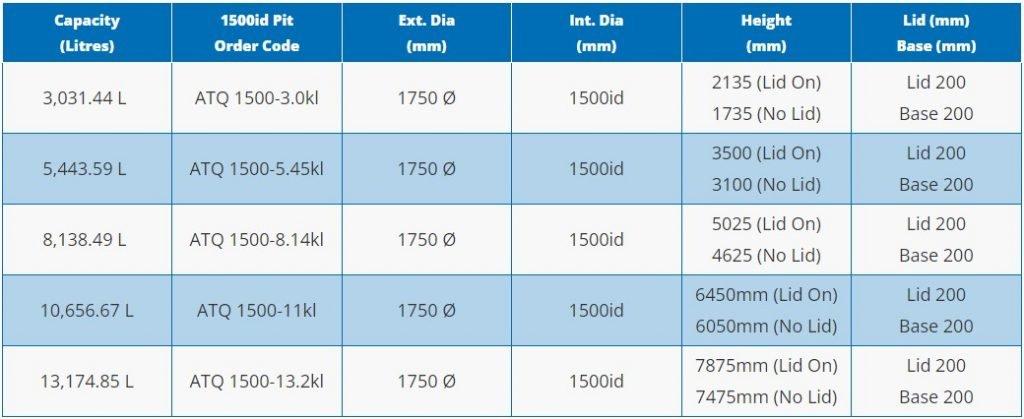

The Australian Tanks 1500mm ID pit is the ideal solution for small grinder pumps through to significant wastewater pumps. Any pump arranged in a dual guide rail mounted set-up serviced by a 900×900 clear opening in the lid should be suitable for the Australian Tanks 1500mm ID pit (Pump manufacturers can confirm suitability).

Maintenance costs over the total life of a pump station can be costly, and run second behind electricity costs. For this reason, it is imperative that just as a pump is selected as close to its best efficiency point, a tank is selected that provides a hydrodynamic efficient pump well.

Problem pump stations are expensive for owners. Callouts for blockages, fouled level control equipment, or frequent requirement for sucker trucks to remove sedimentation can be greatly reduced with the use of a correctly sized wet well – potentially saving end users 1000’s of dollars annually.

Our solutions are designed for small, medium, or large capacities and compete extremely favourably with alternative precast or built-on-site systems. Additionally, the lifecycle costs measure extremely well against alternatives as they are very easy to access, clean and maintain.

Every Australian Tanks system is delivered with weir walls, filtration, penetrations, trash screens, ladders, risers, manholes, drainage holes and orifice plates in place, ready for immediate install in the prepared site excavation. Importantly, all systems are pre-cured with no further waterproofing required. Installation takes place in hours, not weeks, to be connected and backfilled within the same day.

We provide tanks that are made to Australian Standards to allow for restricted heavy vehicle access based:

Our range of tanks are easily interconnected in multiples to create any volume quickly and cost effectively. Every system is certifiable, with increasing numbers of engineers incorporating our systems into their designs due to the structural integrity and multiple efficiencies of our service.

Our products are easily modified to fit the volume required on your project. Along with other on-site parameters we can create the ideal custom solution for you and your team.

A tight diameter allows for a much better hydrodynamic area around the pumps, allowing;

A correctly sized wet well can significantly reduce the total life cycle cost for a client.

The 1500mm ID pit rings are joined in our factory, or on site with a water tight three-stage sealing protocol. The seal prevents water ingress, saving the pumps from running unnecessarily, thus saving power consumption.

All Australian Tanks tanks and pump stations are anti-floatation by design. Once backfilled they can be installed in 100% saturation and will instil nil hydrostatic uplift to the slab above.

For installations where the water table can be above the height of the tank, such as a basement installation, tidal or flood prone locations, some of our tanks can have in excess 3.0m water cover and still resist the hydrostatic uplift, providing nil buoyancy. Once the tank is selected to be suitable for the water table, no estimation is required by installers for the ballasting required, and no separate project management of concrete trucks, or water trucks is required.

Due to the high compressive strength and durability requirements necessary for heavy duty construction, Australian Tanks uses 50Mpa strength concrete in all products manufactured.

Australian Tanks products are rated with a B2 classification, in accordance with Australian Standards AS3735 (Concrete Structures for retaining liquids).

All pump wells can be coated externally if there are acidic soils. Sewer or Trade Waste pump stations can be epoxy coated. As a standard, Australian Tanks epoxy coat with Megapoxy MC, as per our council approved grease traps. Alternatively, we can coat the wet well with other engineer specified products such as; Nitocote (Internal), Oxydur (External), Polyurea, Crystaflex, Carboguard, and Phenolic.

Australian Tanks are regularly requested to replace tanks,pump stations and civil products that have been driven over and damaged.

Many times these products have been installed in non-trafficable areas, such as parks and school ovals, but have been inadvertently driven over, only to find the tank has been unable to bear weight with the resulting damage requiring new tank installation.

To avoid these damaging risks all Australian Tanks products are manufactured as Heavy Duty and rated for where the heaviest vehicle traffic will be a 4 axle twin steer truck (Max GVM 27.5t). Example: Garbage Truck.

If you are interested in finding out more about our pump solutions, please call one of our civil design and business development specialists so they can assist you to develop a CAD driven design for your OSD system.

We also offer 24 hour access to all our technical drawing through our unique Engineers Portal. Sign up for free to day.

Our Engineers Hub is available 24 hours a day, sign in to get all the specific details required, including technical drawings and CAD files to make sure that our product is right for your project.

At Australian Tanks, we take immense pride in being the premier manufacturer of sewer and stormwater pump stations. We understand that when it comes to sewer and stormwater management, there is no one-size-fits-all solution. That’s why we make sure that we only provide high-quality sewer and stormwater pump stations that are engineered with prefabricated and reinforced concrete. This makes them perfect for heavy-duty and heavy vehicle load requirements, as well as allows them to withstand the test of time.

If you’re still not convinced, we invite you to take a look at our portfolio of sewer and stormwater pump stations. These case studies of our solutions are real-world examples of our innovative pump stations in action. They showcase the tangible outcomes we’ve achieved through collaborative efforts with our clients. See for yourself why Australian Tanks is the trusted name in custom-engineered pump stations.

A stormwater pump station is an important component in modern urban infrastructure. These structures are designed to manage excess rainwater, preventing flooding in urban areas efficiently. Stormwater pumps play a pivotal role in safeguarding communities and protecting property from the damaging effects of heavy rainfall.

When rainfall exceeds the capacity of natural drainage systems, the stormwater pump station collects and redirects the excess water into a storage area or drainage network. Using sensors to detect rising water levels, the pumps then activate to drain the water to an appropriate discharge point, which then ensures that the water is safely and efficiently removed from the area.

The main components of a stormwater pump station include pumps, control panels, sensors and a variety of pipes and valves. To gain in-depth knowledge about our sewer and stormwater pump stations, we encourage customers to reach out to us directly or explore our resources section and Engineer’s Hub. These resources provide extensive information about our solutions, helping you understand how our innovative products can meet your specific needs, and keep your community safe from the impacts of heavy rainfall and flooding.

Are you planning for an upcoming project? Our Engineer’s Hub can help you find the product you need, quickly and easily.

Every detail is here for you when you need it, at your own leisure, to help you discover what is the right fit for your project.

Gain access to all the required plans to determine which product meets your needs and be able to specify the solution into your design with downloadable CAD drawings.

Copyright 2024 Australian Tanks Pty Ltd, all rights reserved.