Nick Rees

DIRECTOR / CIVIL ENGINEER

Context Engineering

Australian Tanks products are easy to specify on a drawing – they’re easy to size, and are workable within most site constraints.

We specialise in on-site detention tank systems that are suitable for heavy traffic. Our OSD tanks are available in various sizes, and can be interconnected to create the desired volume quickly and cost-effectively.

Our systems are certified and specified by engineers as they provide exceptional structural integrity and multiple efficiencies for your project.

Every system arrives on site with weir walls, filtration, penetrations, trash screens, ladders, risers, manholes, drainage holes, orifice plates in place with no further waterproofing required – ready for immediate installation in the prepared site.

After installation is completed the OSD system is connected and ready for backfill within the same day.

Designed for small, medium, or large capacities we compete extremely favourably in all areas. The lifecycle costs measure extremely well against alternatives as they are very easy to access, clean and maintain.

If you installation is larger then 150,000 litres, the Parthenon is likely to be the most cost-effective solution.

Australian Tanks also manufacture larger systems consisting of 15,000 – 20,000 – 25,000 and 45,000 litre inter-connectable tanks. These systems are designed specifically for large capacities and to compete with in-situ head to head; achieve a substantial detention system in 1–3 days instead of weeks.

As with all of our products, this comes with heavy duty traffic load ratings in accordance with Australian Standards design codes (AS5100.2) and can be backfilled and bear traffic immediately. No downtime while curing.

Our solutions are designed for small, medium, or large capacities and compete extremely favourably with alternative precast or built-on-site systems. Additionally, the lifecycle costs measure extremely well against alternatives as they are very easy to access, clean and maintain.

Every Australian Tanks system is delivered with weir walls, filtration, penetrations, trash screens, ladders, risers, manholes, drainage holes and orifice plates in place, ready for immediate install in the prepared site excavation. Importantly, all systems are pre-cured with no further waterproofing required. Installation takes place in hours, not weeks, to be connected and backfilled within the same day.

We provide tanks that are made to Australian Standards to allow for restricted heavy vehicle access based:

Our range of tanks are easily interconnected in multiples to create any volume quickly and cost effectively. Every system is certifiable, with increasing numbers of engineers incorporating our systems into their designs due to the structural integrity and multiple efficiencies of our service.

Our products are easily modified to fit the volume required on your project. Along with other on-site parameters we can create the ideal custom solution for you and your team.

Traditionally, OSD installers have heavily relied on ‘block and slab’ solutions to build OSD tanks and systems.

As the necessity for OSD systems has increased, so too has the reliance on those traditional labour and time-intensive block and slab detention tanks.

And, as with all demand increases, the costs have increased for slab work, block walls, suspended roofing and waterproofing.

More importantly the on site occupational health and safety requirements have made it more onerous for builders and contractors – this has also lead to increasing costs as well as the need for considerably more manpower and paperwork for Project Managers on site.

Builders and contractors are fast becoming busier in the ever-growing markets of Sydney, Melbourne, Brisbane and the Gold Coast – time becomes a major asset and lost time costs big money. Open excavations, delayed contractors, bad weather Australia regularly experiences, and the need to find additional components for block and slab systems can all combine to negatively impact building costs and efficiencies.

Over the past three years Australian Tanks has developed and refined

an EASY, FAST & COST EFFECTIVE solution to OSD Tanks.

Due to the massive success of the modular system and the significant civil engineer support of the AT7000 system, Australian Tanks was proud to recently launch the AT12000 system – a larger and more robust 12,000 litre modular tank that can achieve even more substantial and deeper detention solutions in the same EASY, FAST AND COST EFFECTIVE way at an even lower per litre price than the AT7000.

The AT7000 modular system can be installed with all On Site Detention requirements in place, delivered to site pre-cured and with no waterproofing needed, and ready for an install that takes hours, not weeks or months.

Our heavy duty trafficable detention system consists of one, or multiple, 7,000 litre anti-floatation rectangular tanks that are easily interconnected to create any volume quickly and cost effectively. With a lower internal height, the AT7000 tank is perfect for shallow requirements of many small On Site Detention systems.

Every AT7000 system can be engineer certified, with increasing numbers of engineers incorporating our system into their OSD tanks designs. The systems can arrive with weir walls, filtration, penetrations, trash screens, ladders, risers, manholes, drainage holes and orifice plates in place and can be installed and connected ready for backfill within the same day.

These systems are designed for small to medium capacities and compete extremely favorably with alternative precast or built-on-site systems. Additionally, the lifecycle costs measure well against alternatives as they are very easy to access, clean and maintain.

These systems are designed for small to medium capacities and compete extremely favorably with alternative precast or built-on-site systems. Additionally, the lifecycle costs measure well against alternatives as they are very easy to access, clean and maintain.

If you are interested in finding out more about either the AT7000 or the AT12000 systems, please call one of our civil design and business development specialists so they can assist you to develop a CAD driven design for your OSD system.

We also offer 24 hour access to all our technical drawing through our unique Engineers Portal. Sign up for free to day.

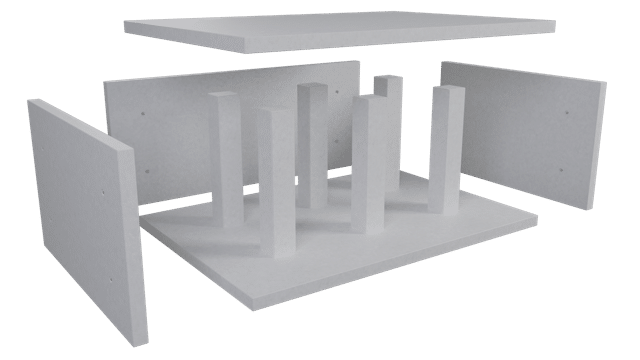

Do you need a cost effective solution for large scale requirements? Our newest offering “The Parthenon” provides unrivalled versatility.

The Parthenon Onsite Detention System is the cost-effective solution for sites where stormwater runoff needs to be captured and detained for controlled discharge from site. Engineered to meet SM1600 Heavy Vehicle Impact loadings, The Parthenon Onsite Detention System allows for maximised use of available land by allowing the detention to be located underneath development sites, carparks, roads or parklands.

The Parthenon Onsite Detention System has been designed with specific consideration given to the safety and health of workmen who will be accessing each tank for ongoing inspections and maintenance. Systems that have a number of parallel chambers have an increased number and frequency of confined space entries.

The Parthenon Onsite Detention System is designed as a single chamber within minimal working obstructions and trip hazards. The single chamber for its entire storage volume minimises the need for multiple entries and exits. Low head-room systems are also available, so care must be taken in matching safe work practices to the inspection and maintenance of these systems.

Sediment and material obstruction removal can be accomplished by either manual extraction or eductor truck (vacuum) extraction. As with all maintenance procedures, suitably qualified technicians following industry regulated procedures should perform the tasks following ‘best practices’ established during job hazard analysis meetings. It should be noted that preliminary design of The Parthenon Onsite Detention System can simplify maintenance procedures. The Parthenon Onsite Detention System can be designed with a slight grade to encourage build-up of sediment to the downstream end of the basin.

Underground stormwater detention is a common application for The Parthenon Onsite Detention System and is well regarded as the solution to meeting legislative requirements for onsite detention without compromising the delivery of high-yield useable land area. The benefits of pre-casting such systems are many-fold and include;

The Parthenon Onsite Detention System has been designed to maximize the desired outcomes of safety-in-design with respect to manufacture, installation and life-cycle maintenance.

The standard Parthenon tank unit is exceptionally versatile and can be further augmented to facilitate other key functions related to the management of stormwater runoff. The entire range of Australian Tanks can be added to suit any requirement.

Filtration Units can be added to the system or additional self-contained Tank Units can be added to house pollutant filtration and removal.

Sediment Fore Bays can be configured into the system to localize the sediment in one area.

Infiltration Openings can be designed into the base panels to allow discharge of the stormwater runoff via soil.

Stormwater Quality Improvement Devices (SQIDs) can be either located upstream, downstream or internally to the system to the system to complete the requirements of the stormwater quality and quantity management plan for the site.

The standard detention tank system can be augmented to facilitate capture and retention of stormwater runoff for harvesting and re-use. The Parthenon can be linked to a range of other water holding tanks from Australian Tanks to fit a range of water holding and detention

objectives.

Self-Cleansing internal pipework can be included within the tank to allow flushing of the system without the need for confined space entry.

Australian Tanks could never have grown to where it is now without our valued customers. Our attention to detail is why our customers keep returning to solve their water storage solutions. We want nothing more than for our customers to enjoy the longevity and efficiency of our commercial water tank solutions, which is why we work as closely with our customers as possible to find the best solution. Check out some of the things our favourite customers have said about us!

At Australian Tanks, our customers are everything. We pride ourselves on providing cutting-edge stormwater storage systems that are made to last. We work closely alongside our customers to ensure they receive the best water storage solutions. But don’t just take our word for it. Check out some of our favourite stormwater management case studies!

Are you planning for an upcoming project? Our Engineer’s Hub can help you find the product you need, quickly and easily.

Every detail is here for you when you need it, at your own leisure, to help you discover what is the right fit for your project.

Gain access to all the required plans to determine which product meets your needs and be able to specify the solution into your design with downloadable CAD drawings.

Stormwater detention tanks or OSD tanks manage and control the flow of stormwater runoff in urban areas. Stormwater runoff occurs when rainwater flows over surfaces such as roads, parking lots and rooftops, where it cannot be naturally absorbed into the ground.

In traditional urban environments, this excess runoff can lead to various problems, including flooding, erosion, water pollution and overwhelmed sewage systems. A stormwater detention tank temporarily stores and slowly releases stormwater runoff to mitigate these issues.

There are several different types of stormwater storage systems, each designed to suit specific site conditions and stormwater management needs. Some of which include:

Not sure which is the right solution for you? Get in touch, and we’d be happy to help. You can also sign up to our Engineer’s Hub to access more information on all of our products, including CAD drawings to download and use in your plans.

Remove accumulated debris such as leaves, trash and other materials from the OSD tank, trash screens and/or filter cartridges. Inspect and maintain the inflow and outflow structures of the tank. And if there are any cracks, leaks or structural damage to the tank, ensure it’s repaired promptly to prevent further deterioration. Staying up to date with the latest developments can also help you determine whether your system requires an upgrade.

Copyright 2022 Australian Tanks Qld Pty Ltd, all rights reserved.